Are you tired of constantly replacing your favorite shoes because they can’t keep up with your daily wear and tear?

Don’t worry, Shoe Goo is here to save the day! This miraculous adhesive has rescued countless soles, damaged heels, and leaky rubber boots from a premature retirement.

You Are Watching: How Long Does Shoe Goo Take To Dry Updated 07/2024

But how long does it take for this wonder glue to do its magic? In this blog post, we will unravel the secrets behind Shoe Goo’s drying time and share tips on speeding up the process.

What Is Shoe Goo?

Uses And Applications

Shoe Goo is a versatile and reliable adhesive that offers multiple uses for shoe lovers. One of its primary applications involves repairing worn out soles, damaged heels, or separated parts in various types of footwear.

This handy adhesive can also be used to provide extra traction by coating skateboards, preventing premature wear on sports gear and sealing small holes in galoshes, waders, or rubber boots.

Waterproof and abrasion-resistant qualities make it ideal for outdoor enthusiasts who want to ensure their gear remains functional through different weather conditions.

How To Apply Shoe Goo

Preparing The Surface

Before diving into the process of applying Shoe Goo to your beloved footwear, it’s essential to prepare the surface for a successful and long-lasting repair.

Follow these steps to ensure a strong bond between your shoe and the adhesive:

- Clean the area: Remove any dirt, dust, or debris from the damaged part of your shoe using a brush or cloth.

- Eliminate any moisture: Make sure that the area you plan to apply Shoe Goo is completely dry by using a hairdryer or allowing it to air dry.

- Remove old adhesive: If there’s existing glue or adhesive on your shoe, use acetone or nail polish remover to clean it off thoroughly.

- Roughen up smooth surfaces: For better adhesion, use sandpaper to slightly roughen up smooth surfaces like leather or rubber soles.

- Mark the application area: To ensure precision during application, outline the area where you intend to apply Shoe Goo with removable tape.

- Practice safe ventilation: Always work in a well-ventilated space when using Shoe Goo due to its strong fumes.

Application Techniques

Proper application of Shoe Goo is essential for achieving the best results when repairing your favorite footwear.

Read More : How To Clean Vessi Shoes Updated 07/2024

Follow these techniques to ensure a neat and efficient application:

- Clean the surface: Remove any dirt, debris, or loose material from the area you’ll be applying Shoe Goo to.

- Apply a thin layer: Start with a small amount of adhesive and evenly spread it across the damaged area.

- Press firmly: After applying, press the two surfaces together firmly to ensure proper adhesion and bonding.

- Smooth out excess: Use a flat tool or your fingertip (covered in petroleum jelly) to smooth out any excess glue around the edges of the repair.

- Allow initial drying time: Let your shoe sit undisturbed for at least 2 hours before handling or attempting additional layers or adjustments.

- Build up layers if needed: For deep repairs, apply additional thin layers after each previous layer has set for 3-4 hours for maximum strength and durability.

- Avoid direct heat sources: While airflow can help speed up drying time, avoid exposing Shoe Goo to direct heat sources such as hairdryers or heaters, as this may cause the adhesive to melt or weaken.

- Exercise patience: Although it’s tempting to wear your newly repaired shoes right away, remember that maximum strength may take 48-72 hours depending on materials and temperature conditions.

Drying Time For Shoe Goo

Factors Affecting Drying Time

The drying time for Shoe Goo can vary depending on several factors. One of the most significant factors that affect drying time is the thickness of the adhesive coating applied.

Another essential factor is humidity levels. High humidity can slow down or even stop the drying process altogether, so it’s best to avoid using Shoe Goo on days with high moisture content in the air.

Lastly, ventilation plays an essential role in how long it takes for Shoe Goo to dry. Adequate airflow helps evaporate solvents faster and speeds up curing times significantly.

By considering these factors and following application tips such as applying thinner coats, ensuring proper ventilation and avoiding humid environments; you’ll achieve optimal results when using Shoe Goo as an effective shoe repair adhesive that restores worn-out soles and heels with ease!

Tips For Faster Drying

If you’re in a hurry, waiting for Shoe Goo to completely dry can be frustrating. Here are some tips to help speed up the process:

- Use a handheld dryer: A hairdryer on low heat can help speed up the drying process, but make sure to hold it at least 6 inches away from the shoe.

- Increase airflow: Placing shoes near a fan or open window can help increase airflow and speed up the drying process.

- Use a heater: Placing shoes in front of a heater can also help them dry faster, but make sure not to place them too close or for too long.

- Thin layers: Applying thinner layers of Shoe Goo can help it dry faster than thicker layers.

- Cut or scrape damaged areas: Cutting or scraping any damaged areas before applying Shoe Goo can help it adhere better and dry faster.

Additional Layers And Precautions

Applying A Second Layer

After applying the first layer of Shoe Goo, you may need to apply a second coat for maximum durability and protection. It is important to wait until the first layer has dried completely before applying the second one.

When adding a second coat, it is recommended to use a thinner amount than the initial application. This will ensure that both layers dry evenly and do not create lumps or bumps on your shoes.

Don’t forget to allow each layer to dry completely for 3-4 hours before adding another coating. Applying more than two coats may cause an uneven finish that can peel off easily.

Safety Guidelines

Here are some tips to keep you safe and maximize the glue’s effectiveness:

- Always apply the adhesive in a well – ventilated area.

- Avoid contact with skin and eyes – use gloves and goggles if necessary.

- If you accidentally get Shoe Goo on your skin, wash immediately with soap and water.

- Do not inhale vapor or spray mist.

- Keep away from open flames or sparks as the solvent in Shoe Goo is flammable.

- Keep out of reach of children and pets.

- Unused Shoe Goo should be stored at room temperature with the cap tightened to prevent damage to finished surfaces.

- Refer to the technical data sheet or safety data sheet for more information on handling, storage, and disposal.

Frequently Asked Questions

Is Shoe Goo Waterproof?

Yes, Shoe Goo is waterproof and acts as a water-resistant adhesive. It can be used to protect shoes from moisture damage or to seal galoshes, waders, rubber boots, and other outdoor footwear from outside elements.

Read More : How To Clean Kizik Shoes Updated 07/2024

The clear adhesive creates an abrasion-resistant synthetic rubber that bonds with porous and nonporous surfaces to ensure long-lasting durability.

Skateboarders love it because it provides extra traction while also being effective in repairing worn-out skate shoes.

Does Shoe Goo Work On Plastic?

Yes, Shoe Goo can work on plastic surfaces. However, it is important to note that applying the adhesive to a scratched or roughened surface will improve its effectiveness on plastic.

It is also recommended to apply thin coats of Shoe Goo and allow each layer to set for 3-4 hours before applying another one.

Additionally, excess mixture should be cleaned off with a cloth or towel and the shoes should be stored in a cool area after application to prevent drying too quickly.

What Will Shoe Goo Stick To?

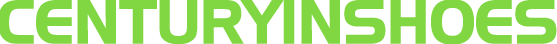

Shoe Goo is a versatile adhesive that can stick to a wide variety of materials. This includes rubber, leather, wood, metal, and many kinds of plastics.

It can also bond porous surfaces like fabric or mesh. This makes it an excellent choice for repairing shoe soles or worn out heels.

Additionally, Shoe Goo provides extra traction for skateboards and other high-wear areas where abrasion resistance is necessary.

However, it’s important to note that Shoe Goo may not be suitable for delicate or expensive materials such as patent leather due to possible discoloration.

Conclusion

In conclusion, Shoe Goo is an excellent solution for repairing and extending the lifespan of your shoes. The drying process can take anywhere from 24 hours to a few days, depending on various factors such as temperature, thickness of the layer applied, and surface type.

To ensure faster drying times, you can use handheld dryers, portable fans or place it in a cold dry environment.

Additionally, applying thin layers instead of thick ones can enhance the drying speed without compromising its effectiveness.

Sources: https://www.centuryinshoes.com

Category: Shoes Care